INSPECTION SERVICES

We tailor our inspections through 3D Photogrammetry, Thermal Imaging, and High Resolution Photography.

We provide critical infrastructure inspection services that include: renewable energy, hydro facilities, telecommunication, structural, and transportation.

Inspection Cycle

Each type of renewable asset presents unique operational and environmental challenges. We recommend tailored inspections anywhere from 2 to 4 times a year depending on the asset. This will ensure optimal performance, and to prevent costly failures. Regular inspections are paramount for maintaining:

- Safety

- Longevity

- Efficiency

Water Management

Water infrastructures such as hydroelectric facilities, dams, reservoirs, levees, pipelines, and treatment plants are essential for supplying clean water, managing flood risks, and ensuring environmental stability. However, these structures are constantly exposed to erosion, material degradation, and extreme weather events, requiring regular inspections to prevent failures. Traditional inspection methods, such as manual surveys, boat-based assessments, and rope-access inspections, can be time-consuming, costly, and hazardous, often leading to delayed maintenance and undetected structural issues.

Transportation Infrastructure

Aging infrastructure, heavy traffic loads, and environmental wear create ongoing challenges for maintaining roads, bridges, railways, and tunnels. Traditional inspection methods often require lane closures, manual surveys, and expensive equipment, leading to disruptions, increased costs, and potential safety risks for workers and the public. Limited access to certain structures further complicates timely assessments, increasing the risk of undetected structural deterioration and costly failures.

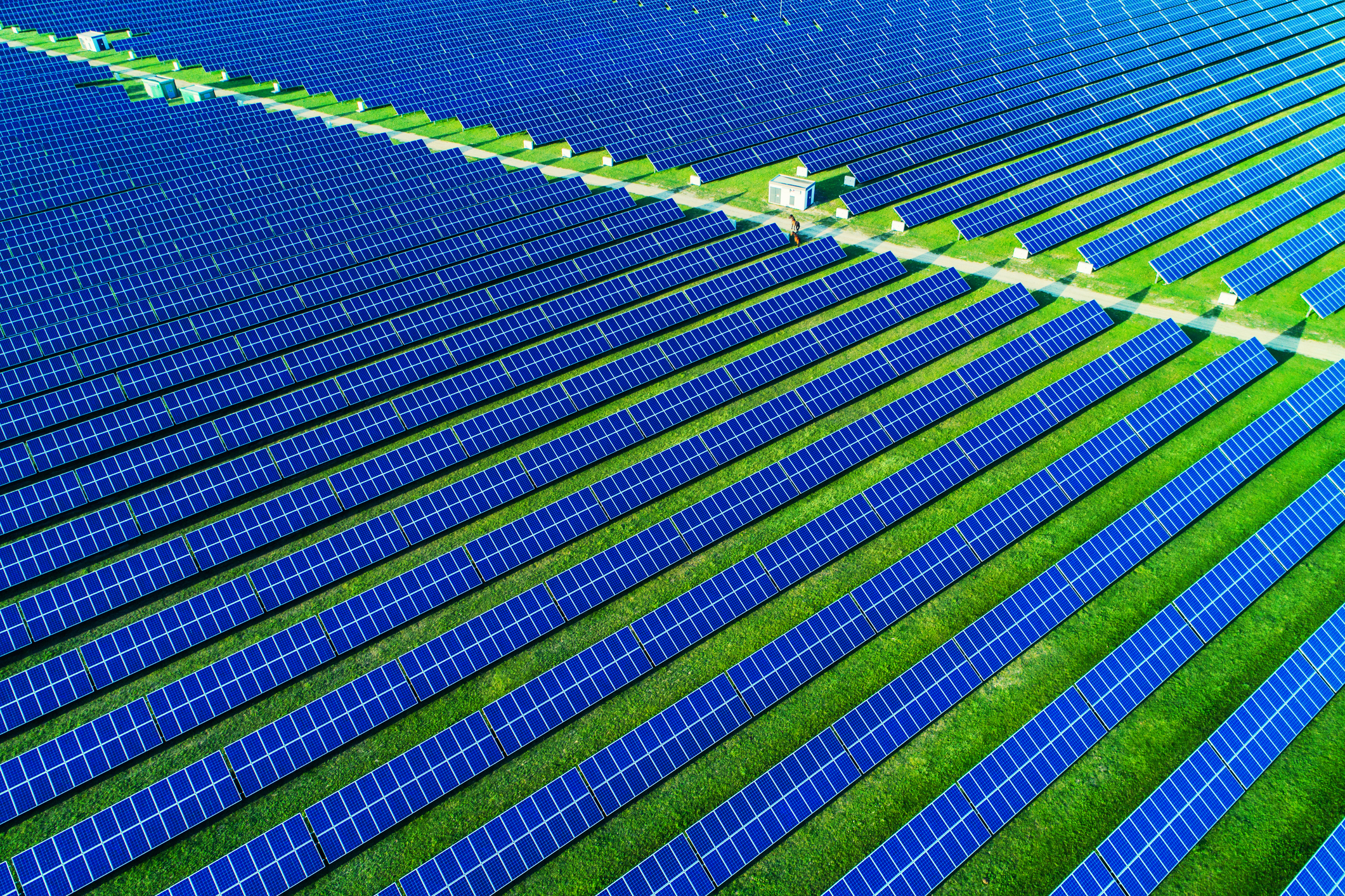

Energy Infrastructure

The energy sector relies on a vast network of solar farms, hydroelectric facilities, power lines, substations. All of which require frequent inspections to ensure reliability, efficiency, and compliance with regulatory standards. Traditional inspection methods, such as manual climbs, helicopter flyovers, and ground-based surveys, are often costly, hazardous, and inefficient. These outdated approaches lead to extended downtime, increased safety risks, and delayed maintenance responses, which can compromise energy distribution and grid stability.

Structural Inspections

Critical projects, cranes, bridges, towers, and industrial facilities, require routine inspections to ensure safety, longevity, and compliance with engineering standards. Traditional inspection methods, including scaffolding, rope-access, and bucket trucks, are often costly, labor-intensive, and hazardous. Additionally, manual inspections can be time-consuming and prone to human error, increasing the risk of overlooked structural weaknesses, delayed maintenance, and unexpected failures.